How to Optimize Bakery Industrial Processes for Maximum Efficiency

In the ever-evolving bakery industrial sector, optimizing processes for maximum efficiency is imperative to stay competitive and meet growing consumer demands. As noted by industry expert, John Baker, a leading figure in bakery innovation, "Efficiency in the bakery industry is not just about faster production; it's about smarter processes that can adapt to changing market needs." This perspective highlights the necessity for bakery professionals to rethink traditional methods and integrate advanced technologies.

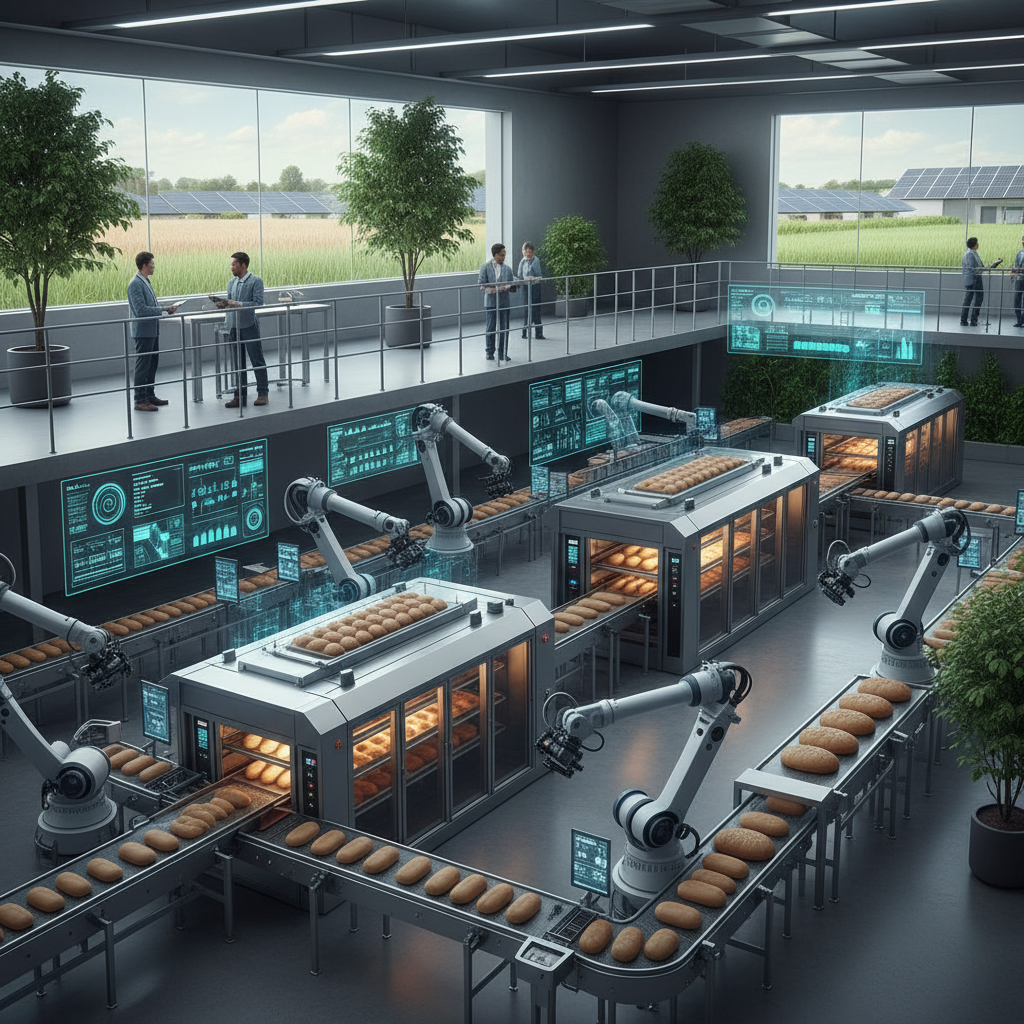

As we move towards 2025, the urgency for optimizing processes in the bakery industrial landscape becomes even more pronounced. With the rise of automation and digitalization, there are unprecedented opportunities for bakeries to enhance productivity, reduce waste, and improve product quality. Professionals within the bakery industrial field must embrace these changes, leveraging data analytics and operational insights to refine their workflows.

In this guide, we will explore effective strategies and innovations that can help bakeries achieve their efficiency goals. By focusing on sustainable practices and the latest advancements in technology, the bakery industrial sector can not only enhance its operational efficiency but also contribute positively to the environment, paving the way for a more sustainable future.

Strategies for Implementing Lean Manufacturing in Bakery Operations

Implementing lean manufacturing strategies in bakery operations can significantly enhance efficiency and reduce waste. One of the primary methods is to streamline processes by mapping the entire production workflow. This allows bakery managers to identify bottlenecks and unnecessary steps, enabling them to eliminate or rearrange tasks that do not add value. For example, adopting a just-in-time approach can help align ingredient delivery with production schedules, minimizing inventory costs and ensuring fresher products.

Another key strategy involves fostering a culture of continuous improvement among employees. Training staff in lean principles encourages them to identify inefficiencies and propose solutions. Regular team meetings can facilitate open discussions about production challenges, leading to innovative ideas that improve workflows. Additionally, integrating quality control measures throughout the production process ensures that any defects are caught early, reducing rework and optimizing resource use. By actively engaging employees in this process, bakeries can create a more responsive and efficient operation, ultimately maximizing productivity and profitability.

How to Optimize Bakery Industrial Processes for Maximum Efficiency

| Process Area | Current Efficiency (%) | Target Efficiency (%) | Improvement Strategies | Notes |

|---|---|---|---|---|

| Mixing | 80 | 95 | Implement automated mixing systems | Consider technology upgrades |

| Baking | 75 | 90 | Use temperature control systems | Evaluate oven efficiency |

| Cooling | 70 | 85 | Optimize airflow and cooling cycles | Monitor humidity levels |

| Packaging | 65 | 80 | Implement high-speed packaging machines | Reduce waste through better materials |

| Inventory Management | 60 | 75 | Utilize software for tracking | Implement just-in-time practices |

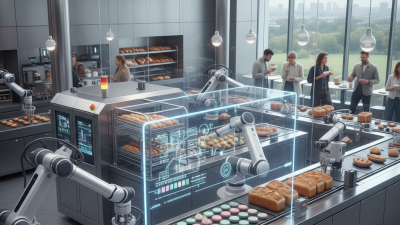

Leveraging Technology: Automation Solutions in the Bakery Industry

In the fast-paced world of the bakery industry, leveraging technology through automation solutions has emerged as a pivotal strategy for optimizing industrial processes. Reports indicate that the global bakery automation market is expected to surpass USD 6.3 billion by 2025, driven by increasing demand for high-volume production and consistent quality. Automation technologies such as robotic systems and conveyor belts enable bakeries to streamline their operations, reduce manual labor, and enhance overall efficiency.

A case study conducted on automated bakeries reveals that integrating robotics can improve production efficiency by up to 30%. This shift not only accelerates the manufacturing process but also minimizes human error, ensuring that products meet stringent quality standards consistently. Furthermore, automation facilitates real-time monitoring of production metrics, allowing bakers to identify bottlenecks and implement corrective measures swiftly. By adopting these modern solutions, bakeries can not only reduce downtime but also increase output, driving profitability in a competitive market.

Energy Efficiency Practices for Reduced Operational Costs in Bakers

Energy efficiency is becoming increasingly essential for bakers aiming to minimize operational costs and enhance productivity. According to the U.S. Department of Energy, bakeries can cut energy costs by 10-20% through effective energy management practices. Implementing simple changes, such as optimizing oven usage and conducting regular maintenance, can drastically improve energy consumption. For example, scheduling regular checks on ovens and cooling systems can identify inefficiencies before they become costly problems.

Tips: During peak production times, bakers should utilize batch baking to maximize oven loads, which not only saves energy but also improves workflow. Additionally, incorporating energy-efficient equipment, such as high-efficiency ovens and refrigeration systems, can yield significant savings over time. According to a report by the American Institute of Baking, switching to newer equipment can potentially reduce energy usage by up to 50%, reinforcing the importance of investing in modern technology.

Moreover, training staff on energy-saving practices can lead to culture shifts within the bakery. A study by the Food Processing Industry Association found that bakeries that foster a culture of sustainability see a 15% reduction in energy costs compared to those that do not prioritize such practices. Simple actions, such as turning off equipment when not in use, can collectively lead to considerable savings. By embedding energy efficiency into the fabric of daily operations, bakers can achieve both financial and environmental benefits.

Data-Driven Decision Making: Utilizing KPIs in Bakery Management

In the bakery industry, data-driven decision making is pivotal for enhancing operational efficiency and maximizing productivity. Key Performance Indicators (KPIs) serve as essential tools in this process, as they provide measurable insights into various aspects of bakery management. By regularly monitoring KPIs such as production output, waste rates, and energy consumption, bakery managers can identify inefficiencies and areas for improvement.

Tips for Utilizing KPIs in Bakery Management: Start by selecting the most relevant KPIs tailored to your bakery operations. Focus on metrics such as dough yield, baking time efficiency, and labor cost per product. Regularly review these metrics and ensure that your team is informed about their implications. This transparency promotes a culture of accountability and encourages staff to contribute to efficiency improvements.

In addition, consider integrating advanced analytics tools to process and visualize your data. This can assist in recognizing trends and anomalies quickly, aiding in proactive decision-making. For instance, if certain baking batches consistently result in higher waste, investigating the associated variables can lead to refined processes that boost overall productivity.

Sustainability Initiatives: Waste Reduction Tactics in Industrial Bakeries

In industrial bakeries, sustainability initiatives play a critical role in enhancing efficiency and minimizing waste. One effective tactic for waste reduction is the implementation of a

comprehensive inventory management system that tracks raw materials, production schedules, and product expiration dates.

By optimizing inventory levels and ensuring the timely use of ingredients, bakeries can significantly reduce spoilage and overstock situations, which are common sources of waste.

This proactive approach not only conserves resources but also cuts costs associated with excess inventory.

Another strategy involves repurposing by-products generated during the baking process. For example, stale bread can be transformed into breadcrumbs or croutons, while excess dough can be

reprocessed into new baked goods. This not only lessens the environmental impact but also creates additional revenue streams for the bakery.

Furthermore, investing in energy-efficient equipment and technologies can change the overarching operational framework.

By prioritizing energy conservation and utilizing equipment that reduces emissions and enhances overall productivity, bakeries positioned for sustainable growth can achieve significant efficiencies without compromising quality.

Related Posts

-

2025 Top 10 Must Have Baking Equipment for Every Home Baker

-

2025 Top 10 Bakery Systems You Need to Know for Your Business

-

2025 Top 10 Essential Baking Goods Every Home Baker Must Have

-

2025 How to Succeed in Commercial Baking with Industry Insights and Key Trends

-

2025 How to Choose the Best Bakery Machines for Your Business Needs

-

10 Best Bakery Machines for Perfect Baking Every Time in 2023