How to Implement Bakery Automation for Increased Efficiency and Profitability

The bakery industry is experiencing a transformative shift towards increased efficiency and profitability through the integration of bakery automation. According to the 2022 **Bakery Industry Trends Report**, automated processes can enhance production speeds by up to 40%, significantly reducing labor costs and improving product consistency. In an era where consumers demand higher quality and faster delivery, automation is not just a trend but a necessity for staying competitive.

Renowned industry expert, Dr. Eleanor Truffet, in her recent seminar on bakery innovation, stated, "Embracing bakery automation is the key to optimizing operations and meeting evolving consumer expectations." This sentiment reflects the growing consensus among industry leaders that investment in automation technology is essential for bakeries looking to thrive in a challenging market. By adopting advanced automated systems, bakeries can streamline their workflows, reduce human error, and increase output, thereby boosting their overall profitability.

As bakeries begin to implement these technologies, it is imperative to understand the best practices for integrating automation effectively. From selecting the right equipment to training staff, the transition to bakery automation requires careful planning and strategy. Doing so not only enhances productivity but also positions bakeries to capitalize on emerging opportunities in a rapidly changing landscape.

Understanding Bakery Automation: Key Concepts and Technologies

Understanding bakery automation is essential for modern bakeries seeking to enhance efficiency and profitability. At the heart of bakery automation are key technologies, such as programmable logic controllers (PLCs), automated mixing systems, and conveyor belts, which streamline production processes. According to a report by the American Bakers Association, implementing automation can reduce labor costs by up to 30% while increasing production capacity. These systems ensure a consistent quality in products by minimizing human error and allowing for precise control over mixing, baking, and packaging processes.

Incorporating data analytics is also transforming bakery operations. Real-time data monitoring allows for better inventory management and maintenance scheduling, leading to reduced waste and improved resource allocation. A study from the International Journal of Food Science revealed that bakeries utilizing automated systems experienced a 20% reduction in ingredient waste.

As bakeries adopt these advanced technologies, they not only enhance their operational efficiency but also adapt quickly to changing consumer preferences, catering to the growing demand for diverse and personalized baked goods. This proactive approach positions bakeries for sustainable growth in an increasingly competitive market.

Identifying Efficiency Goals for Bakery Automation Implementation

Identifying efficiency goals is a critical first step in implementing bakery automation. Establishing clear objectives allows bakers to pinpoint specific areas where automation can lead to enhanced productivity. For instance, consider analyzing the current workflow and identifying bottlenecks, such as slow mixing processes or inefficient baking cycles. By understanding these pain points, bakers can set targeted goals, such as reducing bake time by 20% or improving consistency in dough preparation. This focused approach not only enhances operational efficiency but also lays the groundwork for measuring returns on investment from the automated systems.

Tips: Regularly track production metrics to establish a baseline for performance evaluation. This data provides insight into where improvements are most needed, allowing bakers to prioritize automation initiatives that will yield the highest efficiency gains.

Additionally, involving the entire team in identifying these goals can foster a sense of ownership and collaboration. Employees working on the production floor often have firsthand knowledge of the challenges faced, making their input invaluable. By hosting brainstorming sessions, bakers can gather diverse ideas that may lead to innovative solutions tailored to their unique operations.

Tips: Encourage open communication and feedback from all staff levels. Creating an inclusive environment can lead to greater buy-in when new automated systems are introduced, ensuring smoother transitions and enhanced overall performance.

Choosing the Right Equipment and Software for Your Bakery

Choosing the right equipment and software is crucial for bakeries aiming to implement automation effectively. According to the American Bakers Association, the industry has observed a significant shift towards automation, with over 60% of bakeries reporting improved efficiency and reduced labor costs through modern technology adoption. Selecting equipment that aligns with specific baking processes, such as automated mixers, ovens, and packaging machines, can streamline production lines, allowing bakers to focus on quality and creativity.

Moreover, integrating advanced bakery management software can provide real-time insights into inventory management, production scheduling, and order tracking, which can enhance operational efficiency. A report by IBISWorld indicates that bakeries utilizing such software systems can increase their production capacity by up to 30%. With features like predictive analytics, these tools help bakers anticipate demand, minimize waste, and optimize ingredient use, ultimately leading to higher profitability. Investing in the right combination of equipment and software can provide bakeries not only with a competitive edge but also the flexibility to adapt to changing market trends.

Integrating Automation into Existing Bakery Processes

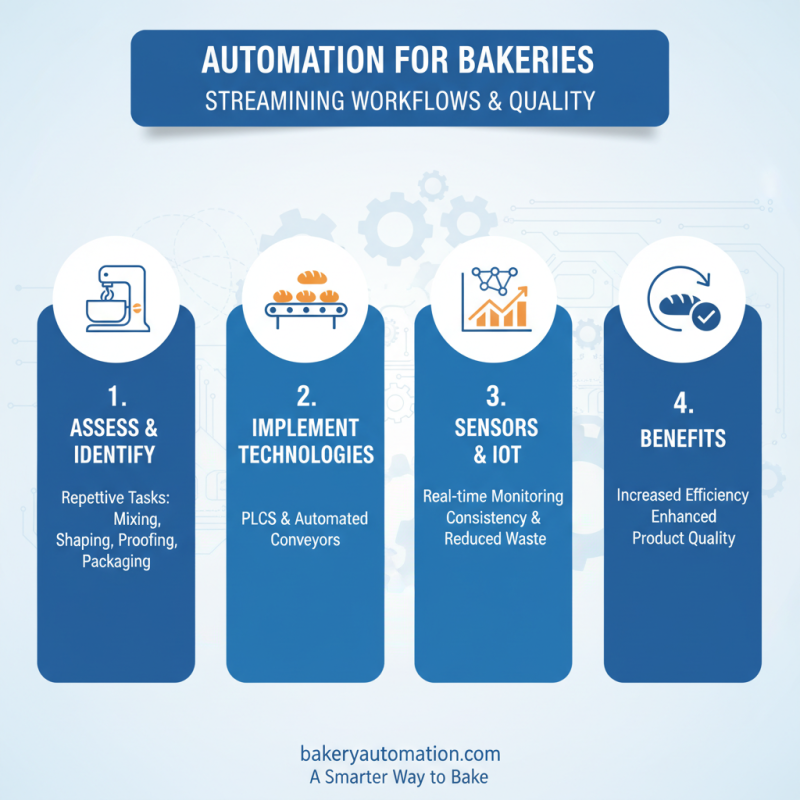

To integrate automation into existing bakery processes, it is essential to start with a comprehensive assessment of current workflows. Identify repetitive tasks that can benefit from automation, such as mixing, shaping, proofing, and packaging. By focusing on these areas, bakeries can significantly streamline operations. Technologies such as programmable logic controllers (PLCs) and automated conveyor systems can be strategically implemented to enhance the efficiency of these processes. Additionally, integrating sensors and IoT devices can provide real-time monitoring of conditions, ensuring consistency in product quality and reducing waste.

Furthermore, the successful integration of automation requires employee training and support. As new systems are introduced, it is crucial to involve staff in the transition process to address any concerns and encourage acceptance. Providing training sessions on the new technology not only boosts confidence but also helps employees understand how automation can enhance their roles rather than replace them. By fostering a culture of collaboration and innovation, bakeries can create a more efficient environment that ultimately leads to increased profitability while maintaining high standards of quality.

Measuring and Analyzing the Impact of Automation on Profitability

The impact of automation on the bakery industry has been profound, significantly enhancing both efficiency and profitability. According to a report by the Food Automation and Manufacturing Association (FAMA), bakeries that implemented comprehensive automation strategies reported an increase in productivity by over 30% within the first year. This boost can be attributed to the reduction of manual labor, which not only speeds up processes but also minimizes human error. As a result, automated systems streamline operations from mixing and proofing to baking and packaging, enabling businesses to scale production without compromising quality.

Moreover, measuring the financial impact of these automation initiatives reveals impressive returns on investment. A survey conducted by the Association for Dressings & Sauces found that automated facilities could reduce labor costs by as much as 25%. In addition to labor savings, the reduction in waste and improved consistency in product quality lead to higher customer satisfaction and retention. As a consequence, bakeries employing automation are not only able to reduce overhead costs but also capture a larger market share, often achieving profitability margins of up to 50% higher than non-automated counterparts. This financial data underscores the critical role that automation plays in shaping a sustainable and profitable future for the bakery industry.

Related Posts

-

2025 How to Choose the Best Bakery Machines for Your Business Needs

-

10 Best Bakery Machines for Perfect Baking Every Time in 2023

-

Top 10 Bakery Systems Tips to Improve Your Business Efficiency

-

How to Implement Bakery Automation for Increased Efficiency and Profitability

-

2025 How to Implement Bakery Automation for Increased Efficiency and Profitability

-

2025 Top 10 Bakery Systems You Need to Know for Your Business